New Lotoke Forged Steel Ball Valve Catalogue

BALL VALVE DESIGN FEATURE

Ball valves are widely used in petroleum refining, chemical, paper making, pharmacy, food, water power, municipal, steel and other industries. Among them, sulfur-resistant series ball valves are particularly suitable for long-distance pipeline for transmission of high-corrosion natural gas with sulphuret hydrogen medium and many impurities.

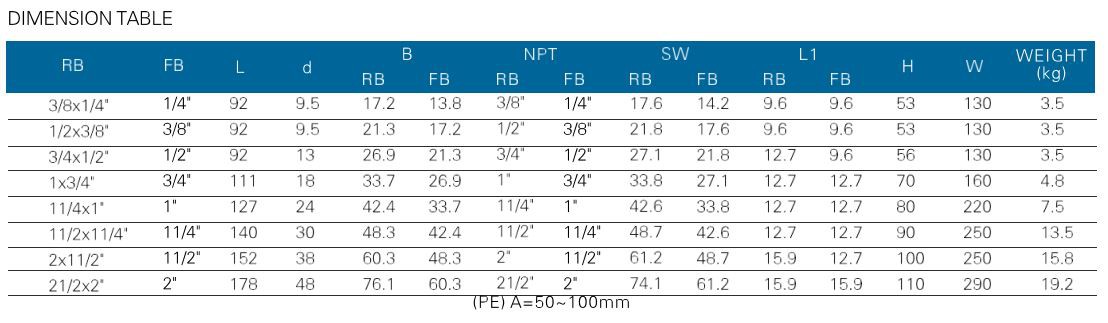

FULL REDUCE BORE

In order to meet different needs of customers, we provide two series of ball valves, full bore and reduced bore ball valves. The channel inner diameter of full bore ball valves is consistent with the inner diameter of pipeline, which can not only minimize the fluid resistance but also facilitate pipeline cleaning.

The fluid resistance of necked bore ball valves is much less than that of the globe valve with the same caliber while its weight is 30 percent lighter than ball valves with the same caliber. As a result, it can effectively reduce both the production cost and price, and is relatively widely used.

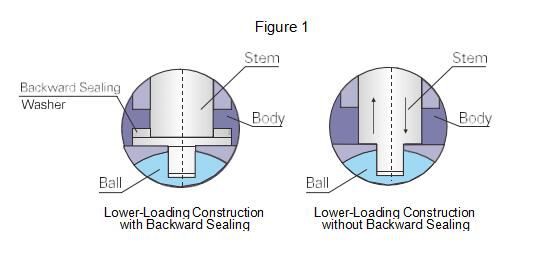

BL .OW - OUT PROOF STEM The stem is downloading, with its inverted sealing structure with sealing gasket. The force of inverted sealing structure will increase while the medium pressure in the valve cavity increases, to ensure the sealing effect of the stem. In case of abnormal pressure increasing of the valve cavity, the stem won't be impacted out. The flr is designed with proper V- -shaped structure, which can effectively convert the medium pressure inside the valve cavity and the locking force of outer gland into the sealing force of stem (Figure 1). |  |

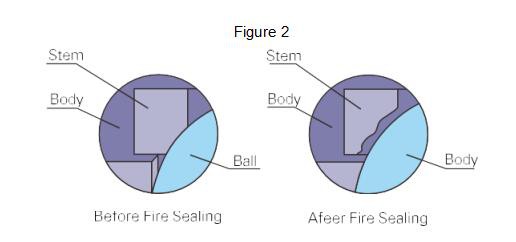

FIRE SAFE SEAT SEALING According to the user's requirement, the ball valve can be designed with fire-resistant structure. In case of a fire and the sealing ring is damaged, every sealing part of the ball valve can form the structure of metal-to-metal hard seal, which can prevent the spreading of both the media and fire (Figure 2). |  |

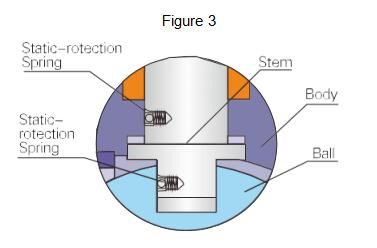

STATIC- PROTECTING CONSTRUCTION The ball valve could be designed as static- protecting construction as required, namely, mounting conductivespring between the globe body and stem, or between the stem and body. There after the static engendered during opening the valve could be conducted to pipelines then earth through the pre -set static passage to clear static away. The design works to prevent igniting combustible medium by static fire-striking for the system safety.(As shown in Figure3) |  |

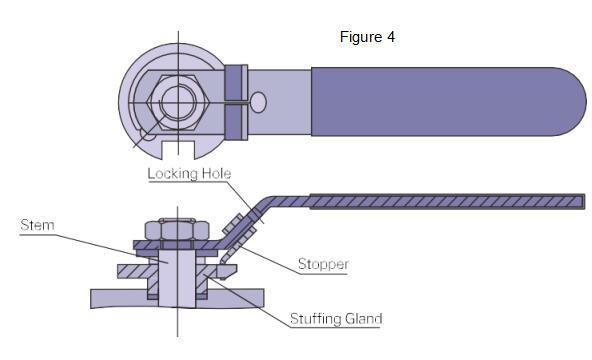

INTERL OCKING DEVICE For valves installdl outdoors,those preventing improper operation non-workers and valves,of which ollision of its stem in relatively violent vibration occasions easily causes improper operation, a locking bore can be set in the fully open position or fully closed position and a lock can be used if needed,for the purpose of ot security insurance (Figure 4). |  |

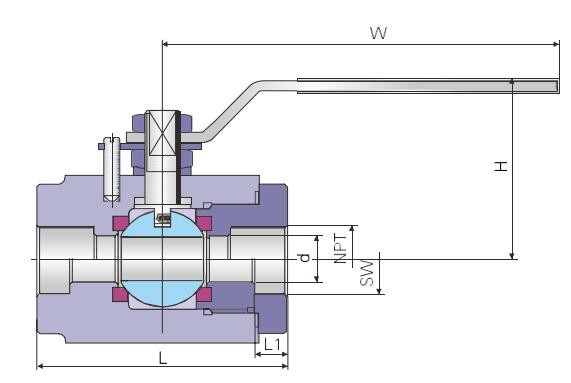

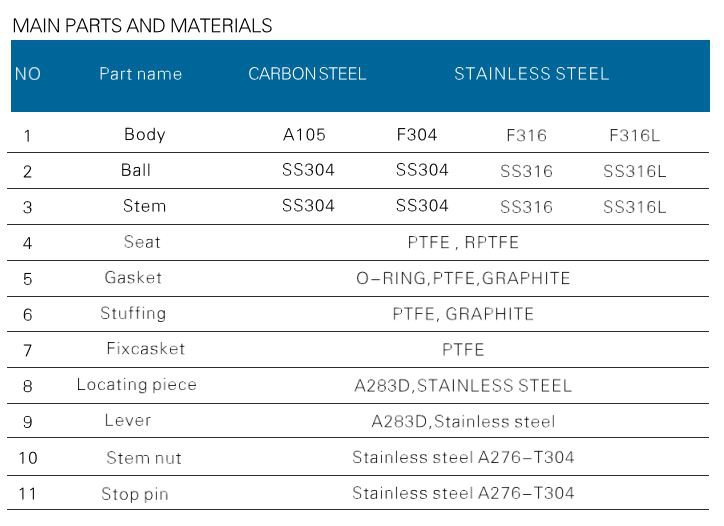

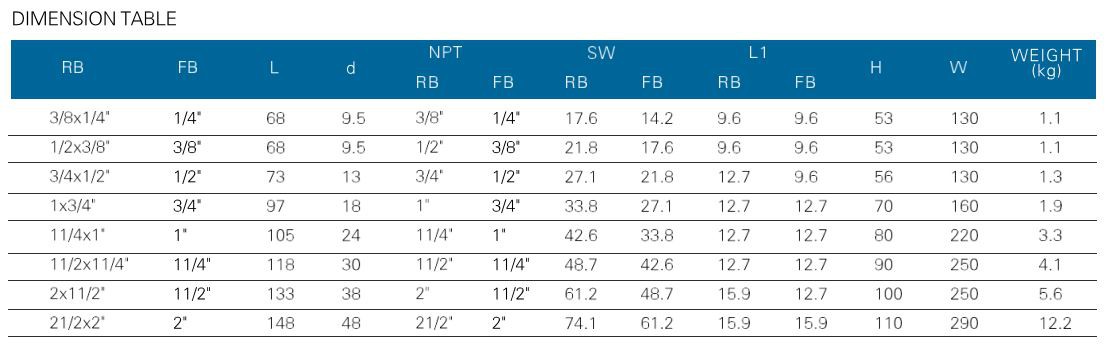

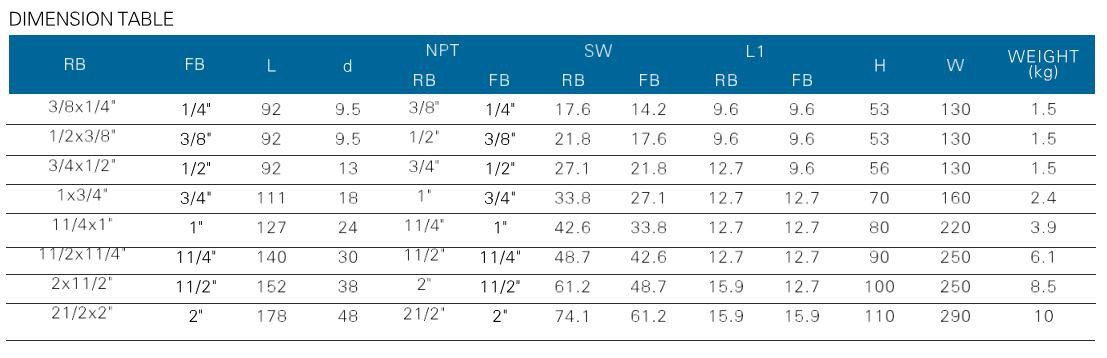

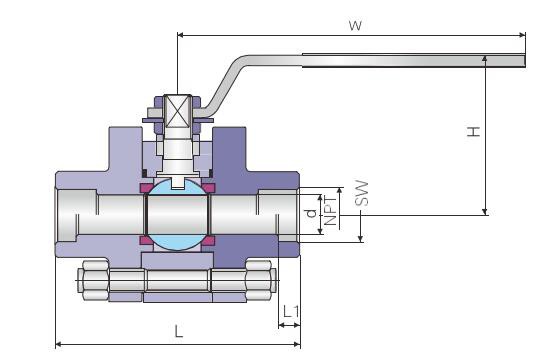

2 PCS FORGED STEEL BALL VALVES 800L .B/1500L ,B

APPLICATION SPECIFICATIONS 1. Design and manufacture conform to BS5351 MSS SP-118 2. Connection ends conform to: 1).Scoket welded ends conform to ANSI B16.11 2).Screw ends conform toANSI B1.12.1 3).Butt-welded ends conform to ANSI B16.25 3. Test and inspection conform to API598 4. Materials conform to ANSI/ASTM |  |

VALVE BODY PRESSURE RATING Class 800,Max 1920 psig@100 degree F Class 1 500,Max 3600 psig@100 degree F |  |

2 PCS FORGED STEEL BALL VALVES 800LB/1500LB

| APPLICATION SPECIFICATIONS 1. Design and manufacture conform toBS5351 MSS SP-118 . 2 Connection ends conform to: 1). Scoket welded ends conform toANSI B16.11 2). Screw ends conform toANSI B1.12. 1 3). Butt-welded ends conform toANSI B16 25 3. Test and inspection conform toAPI598 4. Materials conform toANSI/ASTM |

| VALVE BODY PRESSURE RATING Class 800,Max 1920 psig@100 degree F Class 1 500,Max 3600 psig@100 degree F |

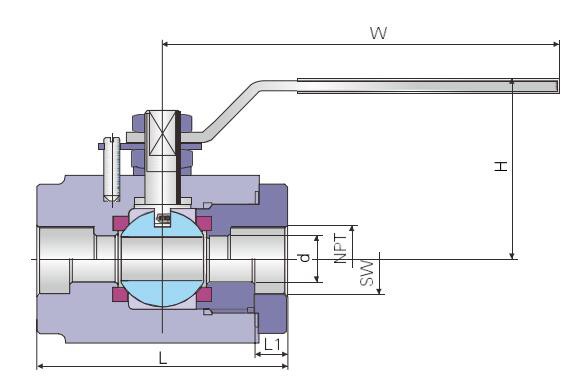

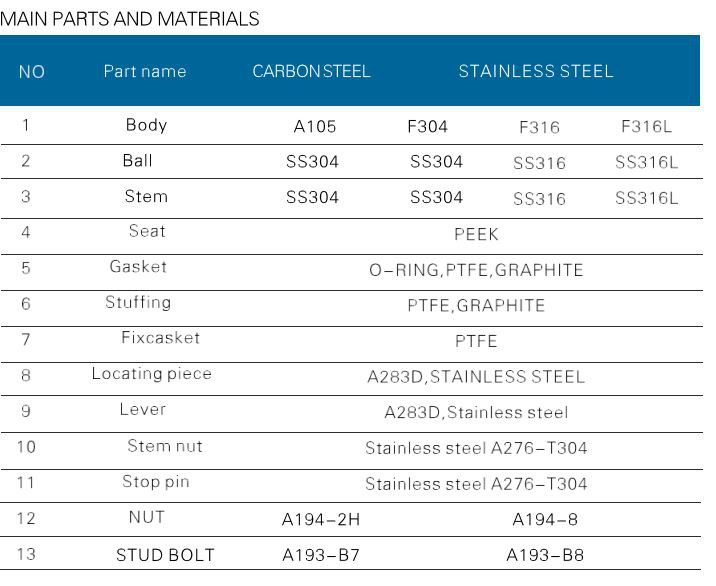

3 PCS FORGEDSTEEL BALL VALVES 2500LB

APPLICATION SPECIFICATIONS 1. Design and manufacture conform to BS5351 MSS SP-118 2 Connection ends conform to: 1). Scoket welded ends conform to ANSI B16.11 2). Screw ends conform to ANSI B1.12. 1 3). Butt-welded ends conform to ANSI B16. 25 3. Test and inspection conform to API598 4. Materials conform to ANSI/ASTM |  |

VALVE BODY PRESSURE RATING Class 2500,Max 6000 psig@100 degree F |  |

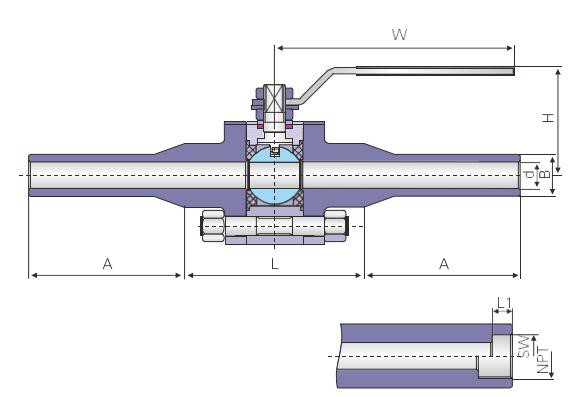

WITH 100MM PIPE ENDS 3 PCS FORGED STEEL BALL VALVES 800LB -1500LB

| APPLICATION SPECIFICATIONS 1. Design and manufacture conform toBS5351 MSS SP-118 2 Connection ends conform to: 1). Scoket welded ends conform toANSI B16. 11 2). Screw ends conform toANSI B1.12.1 3). Butt-welded ends conform toANSI B16. 25 3. Test and inspection conform toAPI598 4. Materials conform toANSI/ASTM |

| VALVE BODY PRESSURE RATING Class 800,Max 1 920 psig@ 100 degree F Class 1 500,Max 3600 psig@100 F |

Populære tags: new lotoke forged steel ball valve catalogue, China, manufacturers, factory, customized, wholesale, price, cheap, in stock, for sale, free sample

Sende bookingforespørsel